Isophthalic acid

Isophthalic acid is an organic compound with the molecular formula C6H4 (COOH) 2. Isophthalic acid is a colorless solid and is a isomer of phthalic acid and terephthalic acid. Isophthalic acid is an important organic dicarboxylic acid for the synthesis of alkyd resins and polyester resins, which is added to the resin reaction to increase the resistance of the resin to water and other chemical agents.

Different isomers of phthalic acid are known by different names:

- Ortho isomer (1,2-benzene carboxylic acid) simple phthalic acid

- Meta isomer, isophthalic acid (1,3-benzene carboxylic acid)

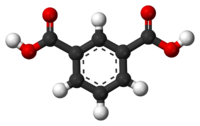

Figure (1) shows the molecular structure of isophthalic acid.

Fig (1): molecular structure of isophthalic acid.

The main and industrial applications of pure isophthalic acid are the production of polyethylene terephthalate (PET) and the production of unsaturated polyester (UPR) and the production of other resins used in the surface coating industry. A mixture of terephthalic acid and isophthalic acid is used for the production of mineral water bottles and food packaging. High efficiency benzimidazole based polymers are produced from isophthalic acid. Other uses for isophthalic acid include:

- Insulation production

- In the production of fiberglass reinforced plastic for products such as pipes and automobiles

- Production of industrial coatings for metal appliances and office furniture

- As an intermediary in the production of unsaturated polyester resins

- Corrosion resistant pipes and tanks

- Used in the production process of benzimidazole-based polymers

Figure (1) shows the production steps of isophthalic acid by oxidation of methazylene using oxygen, in which a cobalt-manganese catalyst is used.

Figure (1): isophthalic acid production by oxidation of methazylene using oxygen

In the field of isophthalic acid production in general, global capacity has significantly exceeded demand and materials will be provided for future demand. Manufacturers say Europe is relatively balanced in terms of allocated capacity, but the United States still has a high capacity and Asia has a subsequent higher capacity. Global capacity is about 750,000 tons per year, while global demand last year was close to 500,000 tons.