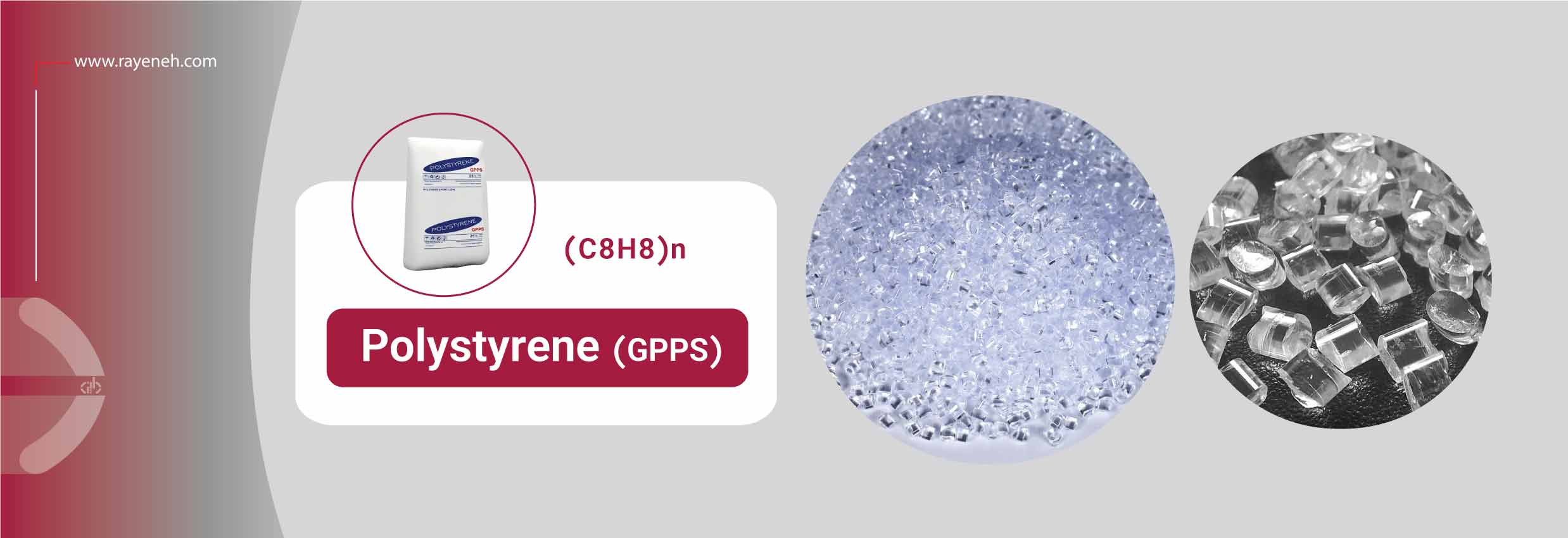

Conventional polystyrene resins are transparent polymers obtained from the polymerization of styrene monomer. Polystyrene GP can be used for both injection molding and extrusion.

The features of this article include the following: Excellent flow properties, high heat resistance, high molecular weight, high transparency, ease of processing, low shrinkage, very low moisture absorption. Technical specifications of general polystyrene (GPPS)

Characteristics

| Molecular formula | (C8H8)n |

|---|---|

| Density (gr/cm3) | 0.96 – 1.04 |

| Melting point (°C) | 240 |

| Melt flow index at 200°C and 5 kg load (gr/10min) | 7 |

| Tensile strength (MPa) | 52 |

| Vicat softening temperature (°C) | 100 |

Application

- Food packing

- Extrusion foam packaging

- Disposable dishes

- Production of household appliances

- Combination with HIPS for FFS thermoforming

- XPS insulation

- Medical laboratory utensils and containers

- Combined with SBS for impact resistant applications

Packing

25 kg bags