Drag reducing agents are chemical additives that, by affecting the rheological properties of the fluid, lead to a reduction in the friction of fluids flowing in tubular beds.

By using friction reducing agents, the amount of friction can be reduced by 60%, so the injection speed will increase with the use of these materials. Friction in pipelines leads to a decrease in flow rate as well as an increase in pumping and energy costs.

Adding a variety of embedded polymers to reduce friction in pipelines during the pumping of crude oil or other chemicals and derived products will make pumping operations easier.

Drag reducing agents also known as friction reducing agents or drag reducing polymers can be broadly classified under the following four categories – Polymers, Solid-particle suspensions, Biological additives, and Surfactants.

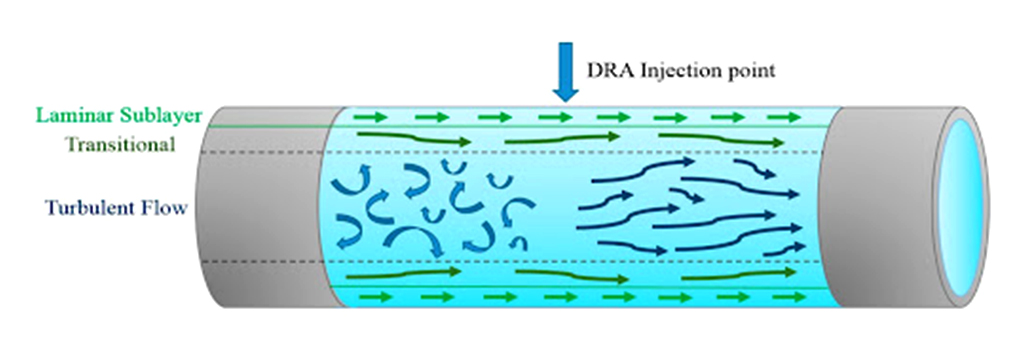

These agents are made out of high molecular weight polymers or micellar systems. The polymers help with drag reduction by decreasing turbulence in the oil lines. This allows for oil to be pumped through at lower pressures, saving energy and money.

Application

Friction reducer in pipelines

Parallelization of flow lines in the turbulent region

Reducing flow loss caused by friction in pipelines

Packing

This chemical is packed in 200 kg barrels, IBC or bags.