Additives

Base oil can be obtained from oil sources or from non-oil sources. Nowadays, most of the base oil is

derived from refining crude oil and the characteristics of base oils derived from crude oil and refining operations.Crude oil contains compounds such as paraffinic, naphthenic and aromatic hydrocarbons, as well as sulfur compounds, base oils are also composed of these compounds. Major oil-base oils that also affect the properties of the lubricant are paraffinic, naphthenic and aromatic compounds.

In terms of volume, base oils are the most important components of lubricants. As a weighted average of all lubricants, they account for more than 95% of lubricant formulations. There are lubricant families (e.g. some hydraulic and compressor oils) in which chemical additives only account for 1% while the remaining 99% are base oils. On the other hand, other lubricants (e.g. some metalworking fluids, greases, or gear lubricants) can contain up to 30% additives.

Base fluids– mineral oil and also synthetic products – generally cannot satisfy the requirements of high performance lubricants without using the benefit of modern additive technology. Additives are synthetic chemical substances that can improve lots of different parameters of lubricants. They can boost existing properties, suppress undesirable properties and introduce new properties in the base fluids. Additives can be classified regarding different aspects. Important and helpful for the understanding of additives is the following differentiation that takes into consideration which part of the tribo system is influenced by the additives.

Additives that add to lubricant may enhance the effect of each other or reduce the effect. The efficiency and quality of a lubricant made of a suitable base oil depends on the type and amount of additives. In the absence of proper quality base oils, additives can not increase the efficiency. Systems with their lubricants will be more efficient and balanced with the right amount of lubricants, and the useful life of the lubricant in these systems is high. The type and amount of additives are very important and they are the secrets of any lubricant production plant. An additive influences the three lubricants and lubrication systems:

• Protect lubrication levels

• Improved lubricant performance

• Increase lubricant life

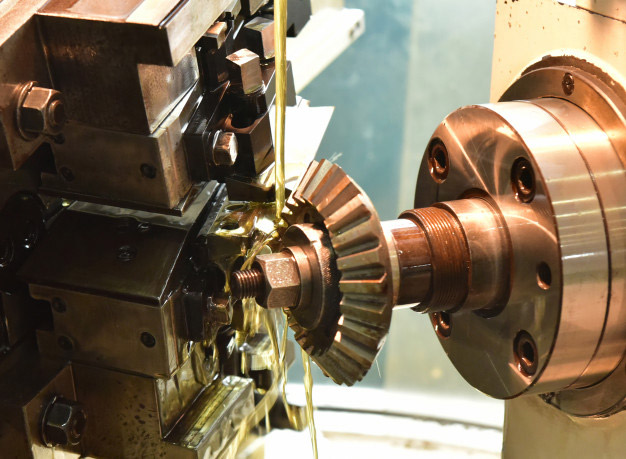

Additives used to protect lubricated surfaces cover the lubricated surface, preventing rust and surface wear. Anti-wear additives, corrosion inhibitors, dispersants and detergents are from this category.

Additives that are used to improve the lubricant’s performance make the lubricant work in special applications. Viscosity enhancers, friction enhancers, and drop-offs are one of those categories.

The last-minute add-ons are additives that increase lubricant life. Oxidation inhibitors that reduce the tendency of oil to oxidize and form sludge, and anti-foaming agents of this type.