De-Emulsifier

The breaking of emulsions (demulsification) is necessary in many applications such as environmental technology, painting, petroleum industry and waste-water treatments. Methods currently available for demulsification can be broadly classified as chemical, electrical and mechanical. Chemical demulsification is the most widely applied method of treating water-in-oil and oil-in-water emulsions and involves the use of chemical additives to accelerate the emulsion breaking process. The formulation of an emulsion demulsifier for a specific petroleum emulsion is a complicated undertaking. In petroleum system, asphaltenes and resinous substances comprise a major portion of the interfacially active components of the oil.

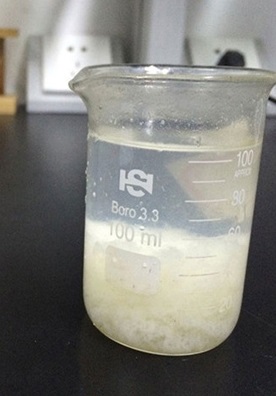

Demulsifiers, or emulsion breakers, are a class of specialty chemicals used to separate emulsions, for example, water in oil. They are commonly used in the processing of crude oil, which is typically produced along with significant quantities of saline water. In other words, Demulsifier is a chemical used to break emulsions that is, to separate the two phases. The type of demulsifier selected depends on the type of emulsion, either oil-in-water or water-in-oil.

This water (and salt) must be removed from the crude oil prior to refining. If the majority of the water and salt are not removed, significant corrosion problems can occur in the refining process. Figure (1) shows the demulsifier mechanism.

Fig. (1): The demulsifier mechanism.

Demulsifiers are typically based on the following chemistry:

- Acid catalysed phenol-formaldehyde resins

- Base catalysed phenol-formaldehyde resins

- Epoxy resins

- Polyethyleneimines

- Polyamines

- Di-epoxides

- Polyols

- dendrimer