Activated carbon

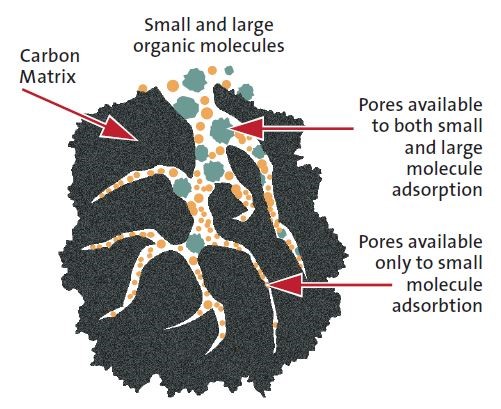

Activated carbon is a group of porous and high internal surface carbon materials that due to their significant internal area, porous and porous structure, high adsorption capacity, surface reactivation capability and also low cost compared to inorganic adsorbents such as zeolite, a unique material. It’s individual. Activated carbon or activated carbon represents a series of surface adsorbents, with a charcoal sex and a crystalline shape, in the internal structure of which there are many holes. Figure (1) shows how the adsorption process in the porous space of activated carbon.

Fig (1): adsorption process in the porous space of activated carbon

Activated Carbon types

- Powdered activated carbon: Powdered activated carbon or activated carbon powder has a size of less than 1 mm and an average diameter of between 0.15 and 0.25 mm.

- Extruded activated carbo: The activated carbon rods or activated carbon are pencil-shaped and have a diameter between 8 and 130 mm.

- Granular activated carbon: Granular activated carbon has a relatively larger particle size compared to powdered activated carbon and therefore a smaller outer surface.

An important advantage of powdered activated carbon is the high amount of active surface per unit volume, but due to the small particle size, it causes a high pressure drop. To make rod activated carbon, powdered activated carbon is bonded together with a bonder and placed inside a cylindrical package. Granular activated carbon is the reason for the high rate of penetration of gases and liquids of this type of carbon for absorption and vapor. Granular carbon is used for water treatment, remediation and separation of materials in streams as well as in fast mixing ponds.

Activated carbon using in gold extraction process

Due to the sensitivity of gold adsorption in the elution system, most gold processing plants use coconut-based activated carbon in gold mining. High adsorption capacity of coconut husk has the highest adsorption capacity and the lowest ash content (ash) among activated carbon, and this property makes this type of activated carbon more efficient in gold mining processes.

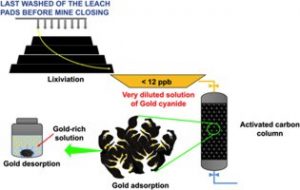

On the other hand, coconut-based activated carbon has high strength and resistance to crushing. Coconut skin has a high strength in its natural state and naturally the resulting activated carbon also has the highest resistance compared to other activated carbon. Therefore, due to the high strength of this material in the gold production process, the amount of gold wasted is reduced. Figure (2) also shows the gold mining process using a coconut-based activated carbon adsorbent.

Fig (2): Gold extraction process using coconut-based activated carbon