drag reducing agent for crude oil (DRA)

Introduction

The phenomena of drag reducing was first observed in 1943.

It was found that by adding small amounts of certain synthetic oil soluble polymers to pipeline systems in turbulent flow there was a substantial reduction in fluid flow resistance, this technology has been developed since 1970’s.

Drag reduction is a phenomenon in which the friction of a liquid flowing in a pipe in turbulent flow is decreased by using a small amount of an additive.

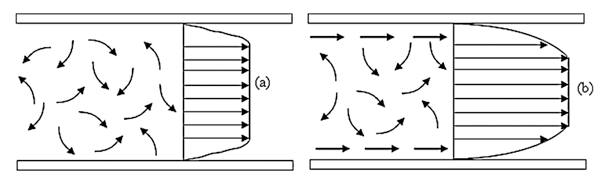

The used drag reducing additives are effective because they reduced the turbulent friction of the solution. This resulted in a decrease in the pressure drop across a length of the pipe and likewise reduced the energy required to transport the liquid, as show in following scheme.

The flow in most crude oil pipelines is turbulent. This means that most of the drag, or energy loss while pumping, is due to turbulent eddies in the oil rather than the friction from pipeline walls. Drag reduction agents are chemicals that are injected into a crude oil pipeline to reduce the energy loss; this produces a solution in pressure drop smaller than that which would occur with untreated solvent moving at the same flow rate.

Drag reduction agents are described as a thick, viscous liquid with the appearance of old honey and highly viscoelastic. DRAs used in oil and products pipelines are themselves hydrocarbons and thus should have no effect on physical properties of refining processes or refined products.

The purpose of using the DRA is improving the fluid-mechanical efficiency in pipelines and also parallelizing the stream lines in turbulent zone. DRAs can be selected from polymers, fibers, or surfactants soap. The advantages of DRA polymers made them more conventional than other DRAs. The most important of these advantages are:

• High molecular weight

• Quick solubility in the fluid pipelines

• High resistance to thermal, chemical and biological decomposition

Drag reducing polymers

More recently the effects of drag reducing polymers on multiphase flows and particularly gas–liquid ones, were investigated where it was found that in addition to pressure drop reduction, the polymers had a significant effect on the flow patterns and their transition boundaries. With the addition of polymer in the water phase, maximum drag reduction was obtained when the slug and annular flow patterns changed to stratified flow.

Waves were dampened in stratified-wavy flows and slug frequencies reduced in slug flow. The liquid hold-up and interface height increased for slug and annular flows; this was attributed to the dampening of the waves which reduced atomization as well as addition from the liquid film that covered the pipe wall in annular flow before the polymer was added.

The results of researcher studies demonstrate that Poly-Alfa Olefins have the best compatibility for using as DRAs. The advantages of using DRA are:

• Facilitating the fluid flowing in pipelines

• Reducing the cost of pumping and energy

• Facilitate the transfer of heavy crude oil

• Increasing the stability of pipelines

Experience using of DRA

A notable application is the addition of 10 ppm of an oil-soluble polymeric additive to the 1.25 m diameter and 1300 km long Trans-Alaskan pipeline in 1979, which led to 50% reduction in pressure drop and eliminated the need for 2 additional pumping stations. Since then, drag reducing polymers have found applications in the Iraq–Turkey oil pipeline and in the Oseberg Field in the North Sea amongst others. These polymeric solutions are injected downstream of a pumping station to avoid degradation and have been found to be environmentally friendly because of their biodegradability.

Conclusion

Drag reduction (reduction of the frictional pressure drop) during fluid flow, is an engineering intervention to decrease the cost of pumping for fluid transportation over long distances. This reduction is accomplished by the addition of small amounts of certain materials such as polymers, fibres or surfactants known as drag reducing agents (DRA) to the flow system. Nowadays, DRAs have also found applications in oil well fracturing operations, district heating and cooling, petroleum loading and offloading as well as in refineries, in pipeline corrosion inhibition, in firefighting, as anti-misting agents in jet fuels, in irrigation and hydropower systems, and in sewage systems to prevent overflow during heavy rain.

[1] A. Al-Sarkhi, Drag reduction with polymers in gas–liquid/liquid–liquid flows in pipes: a literature review, J. Nat. Gas Sci. Eng. 2 (2010) 41–48.

[2] C.J. Manfield, C. Lawrence, G. Hewitt, Drag-reduction with additive in multiphase flow: a literature survey, Multiph. Sci. Technol. 11 (1999) 197–221.

[3] Y. Wang, B. Yu, J.L. Zakin, H. Shi, Review on drag reduction and its heat transfer by additives, Adv. Mech. Eng. 2011 (2011) 1–17.

[4] C. White, M.G. Mungal, Mechanics and prediction of turbulent drag reduction with polymer additives, Annu. Rev. Fluid Mech. 40 (2008) 235–256.

[5] B. Jubran, Y. Zurigat, M. Goosen, Drag reducing agents in multiphase flow pipelines: recent trends and future needs, Pet. Sci. Technol. 23 (2005) 1403–1424.